BEWARE: construction ongoing

Sep 2, 2024

For the past quarter, one of our main focus areas has been the development of our plot of land. When we started developing our site, the land was full of high grass, bushes and rocks. In order for us to turn it into a useful production site, we had to clear it. But that was just the beginning. What else has happened over the past few months?

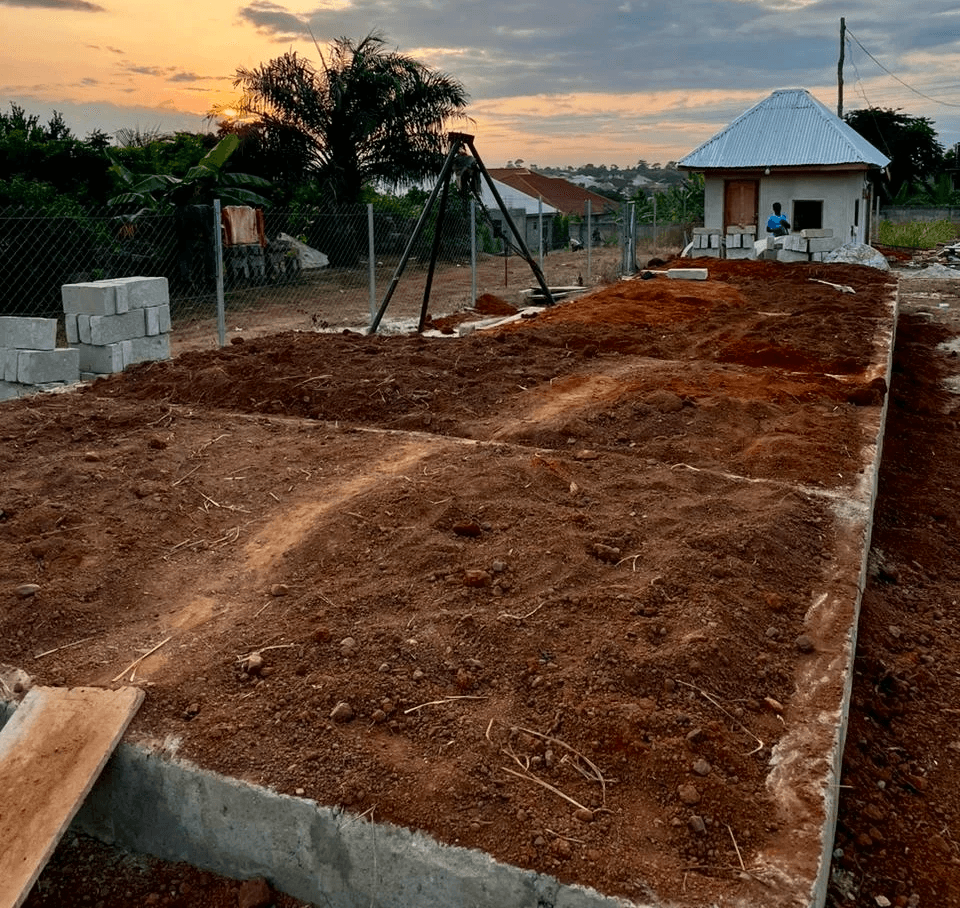

Soon after we set up our partnership with the Kumasi Institute of Tropical Agriculture (KITA), we found a plot of land that was available and ticked all the boxes. First of all, it was just a five to ten minute walk from our house and KITA. Moreover, our first employee Emmanuel is living right next to it, so he is never far away to check out if everything is going well. After we had cleared the land from unwanted grass, bushes and rocks, we put up a fence to prevent unwanted visitors (read: goats, dogs and chickens) from entering. At the same time, we constructed a security post including a sanitary facility. Once our operation will be up and running, the security will make sure that nobody messes with our machinery. Also, we can use the security post as a small office to work. At this moment, however, the security post is mostly used as a storage room for cement and other construction materials.

Because spirulina grows in water, one of our most important facilities to have is a clean water supply. We started with the borehole, for which a big drilling truck came to bore a (80 metres) deep pipeline and therewith gave access to a water source. We also constructed a water tower, which is partly visible in the header. In Ghana, almost every building or house has a tower with a big polytank on top. Water is pumped from the water source into this tank. Once full, the pump can be turned off and, due to the pressure created by the height difference, water can flow easily through your pipes without the usage of electricity. Since our water is used for production, and therefore the risk of any toxins has to be avoided, the water flows through a reverse osmosis filter before entering the polytank. This has led to our facility being one of the few places in Ghana where you can drink straight from the tap.

At this point, we are in the middle of the construction of our processing facility. This building is about 50 square meters, divided into five different rooms. We have designed this facility all by ourselves, based on the processing flow, in line with FDA standards. This means that we have to make a lot of decisions every day: the type of tiles, the places where we put our powers sockets, the material and placement of the windows, and many more. In a timeframe of a few months, we learned a bit of architecture, interior design, plumbing, electrical work, and construction. By now, our operational lead Ruben knows how to mix cement, use a pickaxe, lay pipelines, and many more operational tasks that take place during the development of our production facility.